Design Engineer

Working with a project team, we provided innovative new designs which remain, 25 years later, the core standard product offering at both divisions of EH Wachs.Engineering Manager, Special Projects

Engineering Manager leading a small group of focused, high performance team responsible for all aspects of custom machinery and equipment. Our team would be responsible for the technical sale, the equipment design, assembly, testing and training. Some of our notable accomblishments are highlighted below.

FIND OUT MORE

Engineering

Manager, Special

Projects

Engineering Manager leading a small group of focused, high performance team responsible for all aspects of custom machinery and equipment. Our team would be responsible for the technical sale, the equipment design, assembly, testing and training. Some of our notable accomblishments are highlighted below.Design Engineer

Working with a project team, we provided innovative new designs which remain, 25 years later, the core standard product offering at both divisions of EH Wachs.

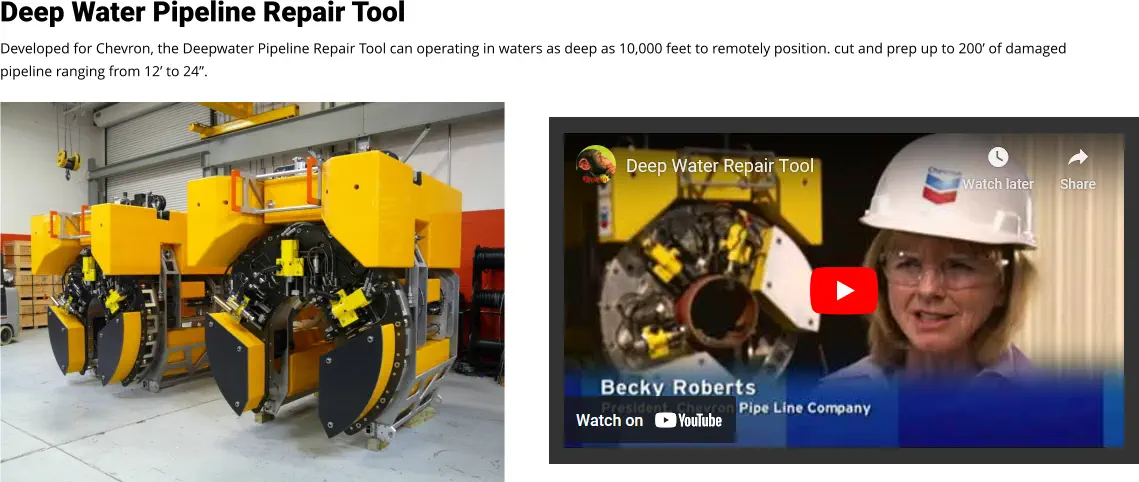

Deep Water Pipeline Repair Tool

Developed for Chevron, the Deepwater Pipeline Repair Tool can operating in waters as deep as 10,000 feet to remotely position. cut and prep up to 200’ of damaged pipeline ranging from 12’ to 24”.

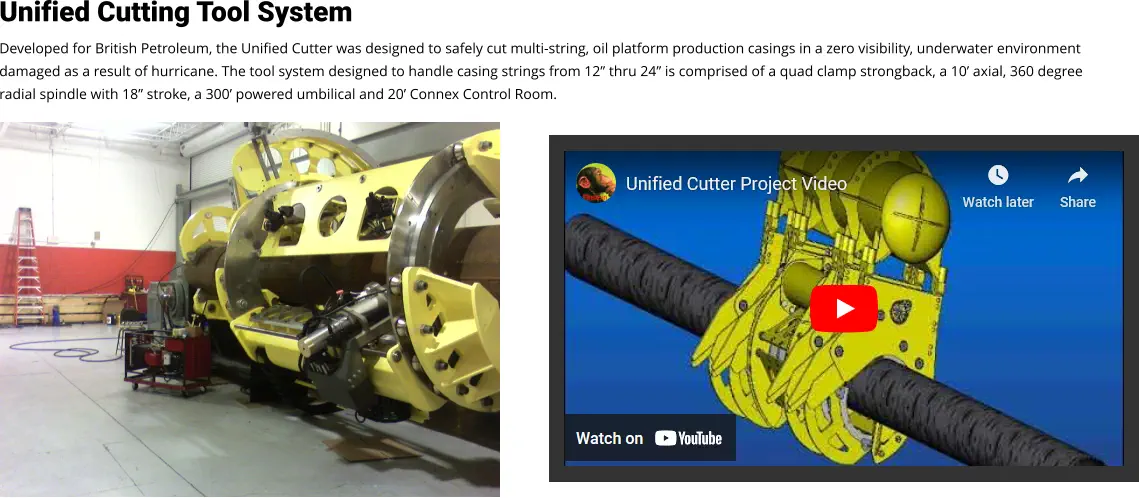

Unified Cutting Tool System

Developed for British Petroleum, the Unified Cutter was designed to safely cut multi-string, oil platform production casings in a zero visibility, underwater environment damaged as a result of hurricane. The tool system designed to handle casing strings from 12” thru 24” is comprised of a quad clamp strongback, a 10’ axial, 360 degree radial spindle with 18” stroke, a 300’ powered umbilical and 20’ Connex Control Room.

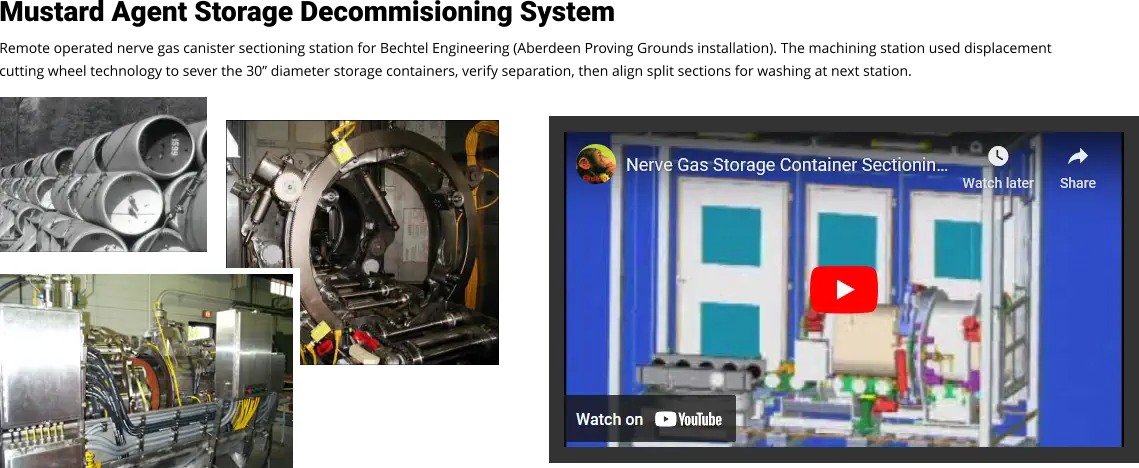

Mustard Agent Storage

Decommisioning System

Remote operated nerve gas canister sectioning station for Bechtel Engineering (Aberdeen Proving Grounds installation). The machining station used displacement cutting wheel technology to sever the 30” diameter storage containers, verify separation, then align split sections for washing at next station.

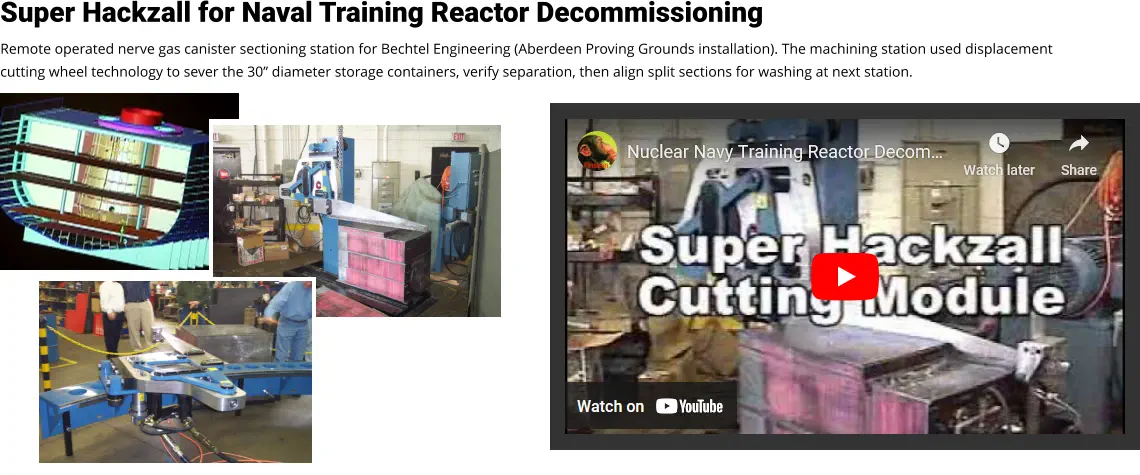

Super Hackzall for Naval

Training Reactor

Decommissioning

Remote operated nerve gas canister sectioning station for Bechtel Engineering (Aberdeen Proving Grounds installation). The machining station used displacement cutting wheel technology to sever the 30” diameter storage containers, verify separation, then align split sections for washing at next station.

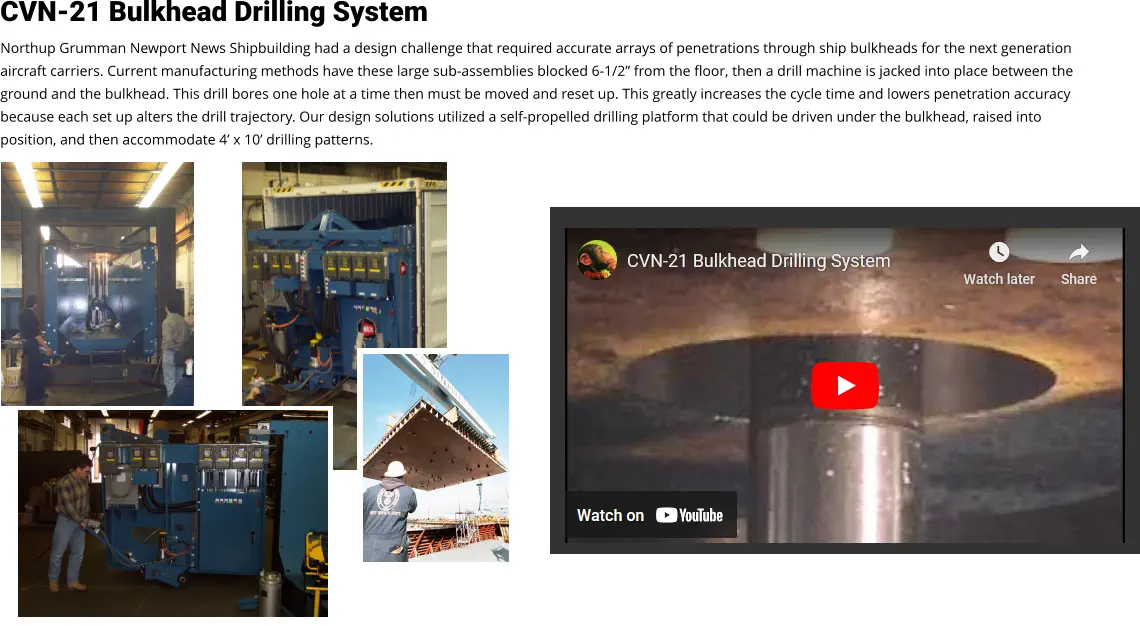

CVN-21 Bulkhead Drilling

System

Northup Grumman Newport News Shipbuilding had a design challenge that required accurate arrays of penetrations through ship bulkheads for the next generation aircraft carriers. Current manufacturing methods have these large sub- assemblies blocked 6-1/2” from the floor, then a drill machine is jacked into place between the ground and the bulkhead. This drill bores one hole at a time then must be moved and reset up. This greatly increases the cycle time and lowers penetration accuracy because each set up alters the drill trajectory. Our design solutions utilized a self-propelled drilling platform that could be driven under the bulkhead, raised into position, and then accommodate 4’ x 10’ drilling patterns.

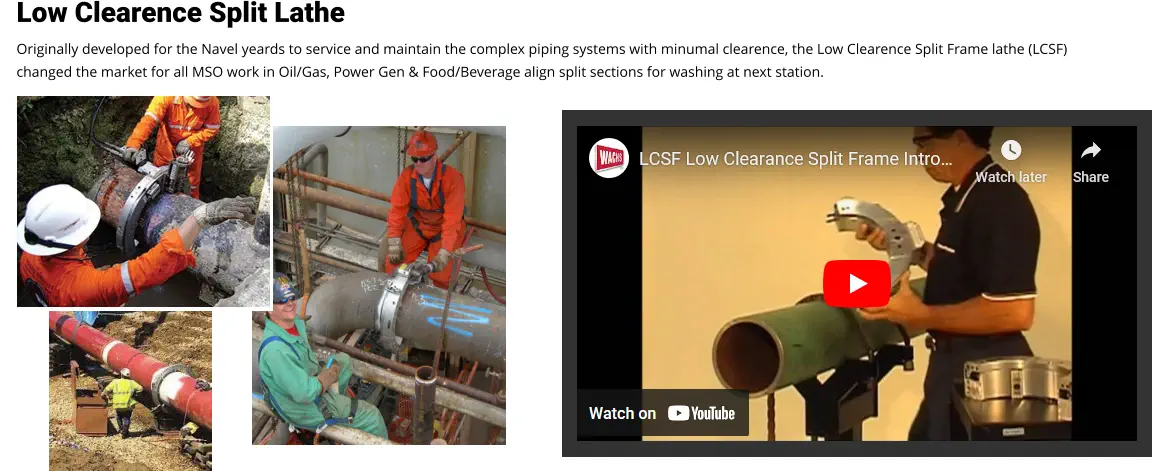

Low Clearence Split Lathe

Originally developed for the Navel yeards to service and maintain the complex piping systems with minumal clearence, the Low Clearence Split Frame lathe (LCSF) changed the market for all MSO work in Oil/Gas, Power Gen & Food/Beverage align split sections for washing at next station.

Valve Box Vacuum

Line of large portable vacuums for local municipalities. These vacuums are normally mounted onto a trailer and are used for cleaning valve boxes. They operate from 300-700 cfm and can generate 15” hg